Call Us+8618020232838

BCF Yarn Spinning Machine

500000.00 INR/Set

Product Details:

- Product Type Spinning Production Line

- Material carbon steel

- Capacity 1-100 T/hr

- Computerized Yes

- Automatic Grade Automatic

- Control System PLC Control

- Cooling System Water Cooling

- Click to View more

X

BCF Yarn Spinning Machine Price And Quantity

- 500000.00 INR/Set

- 1 Set

BCF Yarn Spinning Machine Product Specifications

- 12months

- Spinning Production Line

- Automatic

- carbon steel

- Other

- 1-100 T/hr

- 5000*4000*130000 Millimeter (mm)

- black

- 5000 Milligram (mg)

- Water Cooling

- PLC Control

- 120 Horsepower (HP)

- Yes

- 380 Volt (v)

BCF Yarn Spinning Machine Trade Information

- SHANGHAI

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Western Union, Telegraphic Transfer (T/T), Cash Advance (CA)

- 50-500 Set Per Year

- 60 Days

- Contact us for information regarding our sample policy

- wooden box and plastic film

- North America, Eastern Europe, Middle East, Central America, South America, Asia, Africa

- All India

- CE ISO

Product Description

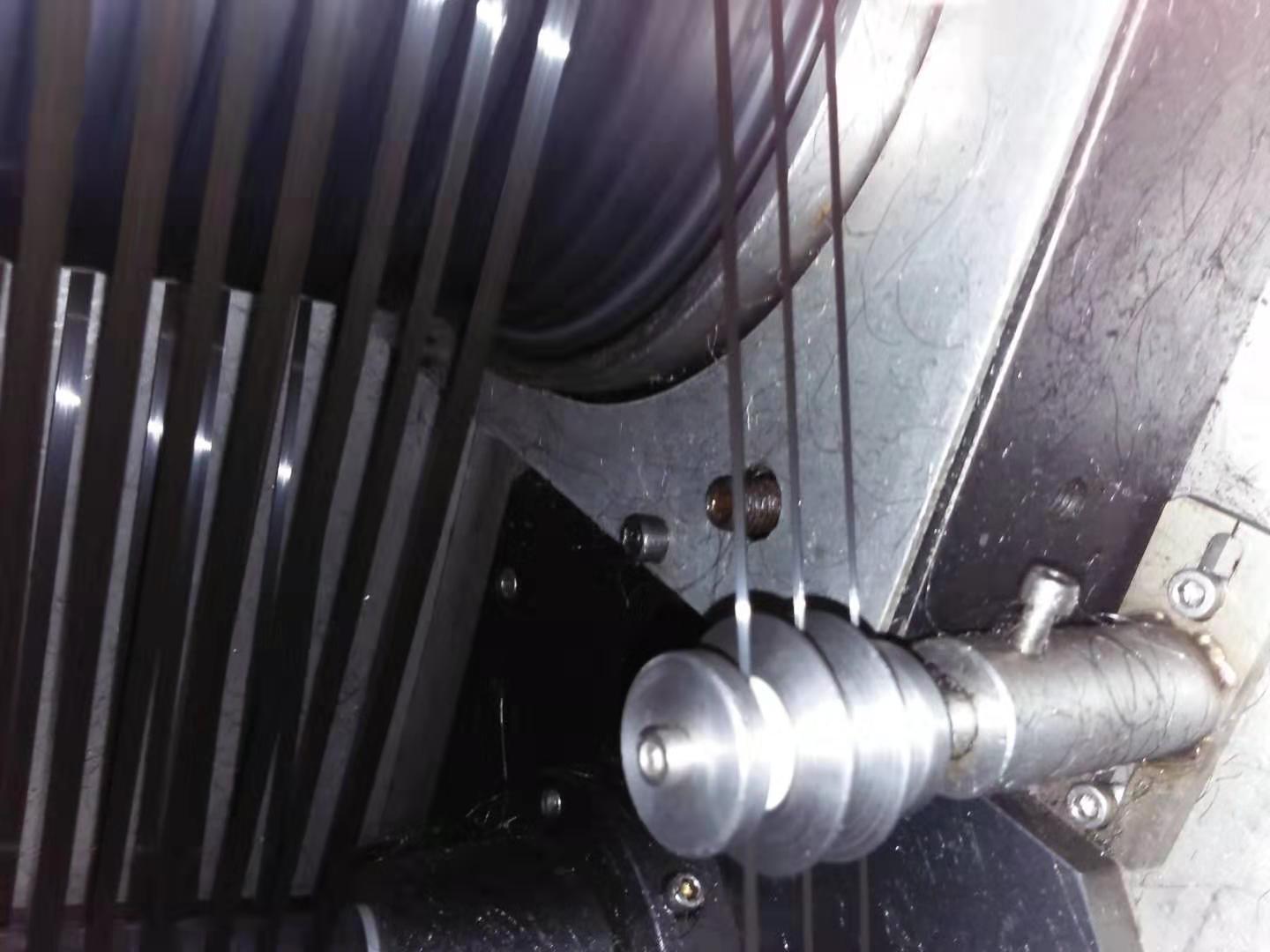

Polypropylene BCF Spinning machine is utilized to make BCF Yarn which is mainly used to make carpet and window seal, etc.

|

Technical Parameters

|

Advanced Automation and Control

Equipped with a state-of-the-art PLC control system and computerized interface, the BCF Yarn Spinning Machine delivers precise, consistent operations. The automatic grade of the machine minimizes human intervention, improving both productivity and reliability.

High Output and Energy Efficiency

Capable of handling up to 100 tons of yarn per hour, the machine's 120 HP motor provides robust performance. The integrated water cooling system maintains efficiency by regulating operating temperatures, contributing to energy conservation and machine longevity.

Superior Build and Versatile Application

Built using high-quality carbon steel, this spinning machine offers durability and resilience. Its adaptability makes it suitable for diverse production environments, supporting manufacturers, importers, exporters, and traders in meeting large-scale demands efficiently.

FAQ's of BCF Yarn Spinning Machine:

Q: How does the PLC control system improve the machine's operation?

A: The integrated PLC control system automates most processes, ensuring precise, consistent yarn spinning with minimal manual intervention. This results in improved efficiency, reduced error rates, and greater ease of use for operators.Q: What is the production capacity of the BCF Yarn Spinning Machine?

A: This machine can produce between 1 and 100 tons of yarn per hour, making it suitable for both medium and large-scale manufacturing needs.Q: When is it recommended to perform maintenance on the machine?

A: Routine maintenance should be conducted according to the manufacturer's guidelines, typically every few months, to maintain optimum performance and to utilize the 12-month warranty effectively.Q: Where can this machine be installed and operated?

A: Owing to its large dimensions and power requirements, this machine is best suited for industrial production facilities with adequate space, ventilation, and electrical infrastructure.Q: What is the installation process for the BCF Yarn Spinning Machine?

A: Installation involves positioning the machine in a prepared space, connecting it to 380V power, integrating the water cooling system, and configuring the PLC controls-usually handled by professionals or with manufacturer support.Q: How is the BCF Yarn Spinning Machine predominantly used?

A: It is primarily used to spin bulk continuous filament (BCF) yarn in textile manufacturing, serving a vital role for distributors, exporters, and manufacturers seeking high-volume, automated production.Q: What benefits does the automatic functionality offer?

A: Automatic operations streamline production, reduce labor costs, enhance safety, and assure consistent yarn quality, positioning businesses to meet high-volume orders efficiently.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'BCF Spinning Machine' category

"Our main international markets are Turkey, five countries in central

Asian, Egypt, Tunisia, Algeria,Vietnam, Indonesia, Pakistan and all the

countries in Latin America."

|

JIANGXI HONGYUAN MACHINERY CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |