High-Tenacity Polypropylene FDY Spinning Machine

Product Details:

- Product Type Spinning Production Line

- Capacity 1-100 Cubic Meter (m3)

- Computerized Yes

- Automatic Grade Automatic

- Control System Human Machine Interface

- Cooling System Air Cooling

- Click to View more

High-Tenacity Polypropylene FDY Spinning Machine Price And Quantity

- 1000000 INR/Set

- 1 Set

High-Tenacity Polypropylene FDY Spinning Machine Product Specifications

- Air Cooling

- Yes

- 1-100 Cubic Meter (m3)

- Automatic

- Human Machine Interface

- Spinning Production Line

High-Tenacity Polypropylene FDY Spinning Machine Trade Information

- shanghai

- 120 Set Per Month

- 90 Days

- Wooden box + Plastic Film

- Western Europe Australia Asia Central America North America South America Middle East Eastern Europe Africa

- All India

Product Description

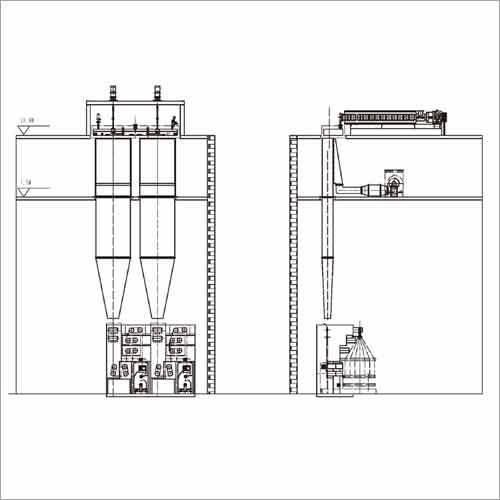

The High-Tenacity Polypropylene FDY Spinning Machine has been specially developed to suit various spinning requirements of textile industry. Equipped with latest features, this spinning equipment has received appreciation of our customers for its high production rate, reliable operation, high performance level and low noise functioning. The easy to adjust parameters of this spinning machine simplifies its controlling method. Long working life and high speed operation of this machine helps to save energy usage and labor cost. We are reckoned as an eminent manufacturer and exporter of superior grade High-Tenacity Polypropylene FDY Spinning Machine.

Features

- The provided machine generates minimal noise

- High output level and user friendly design are some of its key features

- Durable structure

- Long working life

High-Tenacity Polypropylene FDY Spinning Machine

High-Tenacity Polypropylene FDY spinning machine is utilized to make FDY yarn which is mainly used to make woven geotextile, filter cloth, cloth bags, fire hoses, belts, conveyor belts, safety net, industrial sewing thread, marine ropes etc.

- Screw is lengthened, frequency and pressure regulating instruments are imported brands

- A new energy-efficient spinning bean is utilized, which is much more energy saving than regular spinning beam.

- Top-mounted spinning back, which is easy for workers to make spinning operation.

- Chamber quenching system, air is uniform which is good for filament.

- Induction or high-frequency hot godet is used to save energy consumption.

- PP Yarn Spinning Machine

- Multi-level drawing and heat-set way to meet a variety of performance of propylene FDY spinning. Spinning tenacity greater than or equal to3.5g/d

- Using automatic winder, high bobbin winding handover rate, low waste yarn, easy forming.

- Temperature thermometers and inverters are imported brands.

Technical Parameters

|

Item |

Unit |

Parameters |

|

Density |

Denier |

2001200 |

|

Spinning speed |

mmin |

20002800 |

|

Endsposition |

|

6812 |

|

Diameter of Spinneret |

mm |

100150 |

|

Diameter of screw |

mm |

80120 |

|

Diameter of drawing godet |

mm |

190 |

|

Model of Winder |

|

635835 |

|

Capacity per position for 1000D |

Td |

19T26T38T |

Other Products in 'FDY Yarn Spinning Machine' category

|

JIANGXI HONGYUAN MACHINERY CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |