Polyester FDY Civil Spinning Machine

Product Details:

- Material Stainless Steel and High Strength Alloy

- Capacity 800-1200 T/Y Tons/year

- Computerized Yes

- Automatic Grade Automatic

- Cooling System Cross Flow Fan Cooling

- Spinning Method Filament Direct Spinning

- Voltage 380 V / 50 Hz Volt (v)

- Click to View more

Polyester FDY Civil Spinning Machine Price And Quantity

- 900000 INR/Set

- 1 Set

Polyester FDY Civil Spinning Machine Product Specifications

- Filament Direct Spinning

- 250 kW Watt (w)

- Blue & Silver

- 380 V / 50 Hz Volt (v)

- Yes

- Automatic

- 800-1200 T/Y Tons/year

- Cross Flow Fan Cooling

- Stainless Steel and High Strength Alloy

Polyester FDY Civil Spinning Machine Trade Information

- 120 Set Per Month

- 90 Days

- Western Europe, Australia, Central America, North America, South America, Middle East, Eastern Europe, Asia, Africa

Product Description

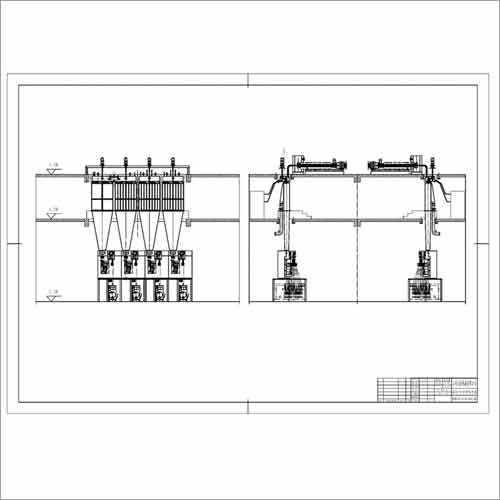

Polyester FDY Yarn Civil Spinning Machine

The Polyester FDY Civil Spinning Machine offered by us is the perfect combination of technology and utility. Developed by using standard grade metals like low carbon steel and stainless steel, this precisely designed spinning machine is appreciated for its high productivity level. Made as per the industry specified standards, this spinning equipment is equipped with automatic controlling system to ensure about its error free operation and to avoid its mechanical damage. Long working life and ease of maintenance are some of its key attributes. We are counted as a prestigious manufacturer and exporter of superior grade Polyester FDY Civil Spinning Machine.

Features:

- The offered machine is notable for its compact appearance

- Easy to comprehend operating system and reasonable price are some of its main features

- Cutting edge mechanism

- High output level

Equipment for the production of polyester FDY FDY yarn that is mainly used for clothing, bedding, decorative items, industrial geo textiles, filter cloth.

The main features

- The machine uses a new type of energy-efficient spinning box than regular spinning boxes can be energy efficient.

- Bottoms advanced cup assemblies, improved melt flow uniformity within the package, the plate surface temperature uniform. While reducing the labor intensity.

- The new side of the hair system, wind uniformity and stability, the fiber of the stem.

- Average temperature of heat pipe technology using hot draft roller, the hot roller surface temperature of the work area uniform and reliable, low energy consumption.

- Slow cooling individually controlled heating device, effectively prevent skin-core fiber structure.

- Multi-level drawing and heat setting mode can meet the requirements of a variety of combinations of different properties of polyester yarn. With the Division of injection molding machines, to facilitate the production of many varieties, small quantities of colored polyester yarn.

- Using automatic winder, handover success rate, low waste silk, forming well.

Technical Specifications

|

Item |

Unit |

Parameters |

|

Density |

Denier |

150300 |

|

Spinning speed |

mmin |

38004400 |

|

Ends position |

|

8101216 |

|

Diameter of spinneret |

mm |

110 |

|

Diameter of screw |

mm |

80105 |

|

Diameter of drawing godet |

mm |

220 |

|

Model of winder |

|

835 |

|

Capacity per position for 150D |

|

08T12T16T |

Enhanced Production Efficiency

Outfitted with an automatic metered feeding system and precision winders, this FDY spinning machine significantly boosts productivity while ensuring uniform quality across diverse denier ranges. Its advanced PLC touch screen control and centralized lubrication system minimize manual interventions, reduce maintenance downtime, and increase operational reliability for both industrial and civil yarn applications.

Top-Tier Safety and Reliability

Safety features like emergency stop and safety guards are integrated to safeguard operators during production. Ceramic-coated godet rolls and robust cooling systems contribute to consistent filament quality and machine longevity. Manufacturers benefit from a secure, stable operation, supporting uninterrupted high-speed output up to 4000 m/min with enhanced protection mechanisms.

FAQs of Polyester FDY Civil Spinning Machine:

Q: How does the automatic precision winder improve the spinning process?

A: The automatic precision winder ensures consistent and even winding of filament yarns, minimizing manual handling and improving the overall efficiency and quality in the spinning process.Q: What is the benefit of using multi-stage, ceramic-coated godet rolls in this spinning machine?

A: Multi-stage, ceramic-coated godet rolls provide better filament control, durability, and reduced friction, resulting in higher yarn quality and longer service life for the equipment.Q: Where can the Polyester FDY Civil Spinning Machine be installed and who provides installation services?

A: Installation services for this machine are available throughout India, and can be coordinated by manufacturers, distributors, or suppliers to ensure proper setup and commissioning at your production facility.Q: When is it recommended to use the centralized automatic lubrication system?

A: The centralized automatic lubrication system is active during machine operation, continuously providing necessary lubrication to critical components, helping maintain smooth function and extend equipment longevity.Q: What safety mechanisms are included in the machine for operator protection?

A: The machine is equipped with emergency stop buttons and a safety guard system, ensuring rapid response during any operational hazard and maintaining a secure work environment for operators.Q: Can this machine produce a variety of filament yarns for both industrial and civil applications?

A: Yes, with its denier range of 30-300 and filament direct spinning capability, this machine is suitable for producing high-tenacity yarns for various industrial and civil uses.Q: How does the PLC touch screen control system enhance usability?

A: The PLC touch screen control system streamlines operation by providing intuitive machine monitoring and adjustment, simplifying process management and reducing training time for operators.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'FDY Yarn Spinning Machine' category

|

JIANGXI HONGYUAN MACHINERY CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |