Stainless Steel Hollow Fiber Spinning Spinneret

200.00 - 2000.00 USD ($)/Piece

Product Details:

- Diameter Custom (as per order)

- Thread Type Fine Thread

- Automation Grade Manual / Semi-Automatic

- Tensile Strength High

- Size Customizable as per requirement

- Features Corrosion resistant, Precision engineered, Durable

- Capacity High Output

- Click to View more

X

Stainless Steel Hollow Fiber Spinning Spinneret Price And Quantity

- 10 Piece

- 200.00 - 2000.00 USD ($)/Piece

- Available

- Excellent

- 0.02 mm to 1 mm (customizable)

- CNC Machined

- Up to 350°C

- Easily detachable for cleaning

- Hollow Fiber, Synthetic Fiber

- ±0.01 mm

Stainless Steel Hollow Fiber Spinning Spinneret Product Specifications

- Fine Thread

- Custom (as per order)

- High

- Depends on specifications

- Manual / Semi-Automatic

- High Output

- Low

- Customized

- Corrosion resistant, Precision engineered, Durable

- Customizable as per requirement

- Spinneret

- Good

- Alloy Steel

- Textile Machinery Accessories

- Polished

- As per customer requirement (multi-hole option available)

- Hollow Fiber Spinning Machine

- Spinneret

- Industrial

- Clamp Mount

- 55-60 HRC

- High-speed compatible

- Available

- Excellent

- 0.02 mm to 1 mm (customizable)

- CNC Machined

- Up to 350°C

- Easily detachable for cleaning

- Hollow Fiber, Synthetic Fiber

- ±0.01 mm

Stainless Steel Hollow Fiber Spinning Spinneret Trade Information

- 120 Piece Per Month

- 90 Days

- wooden box + plastic film

- Asia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Australia, Africa

- All India

Product Description

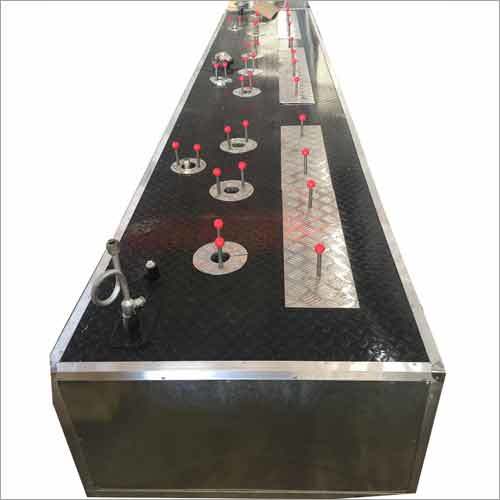

The ergonomically designed Stainless Steel Hollow Fiber Spinning Spinneret is used as an important part of spinning machine for producing staple fiber, differential fiber, nylon, non woven fiber and filament yarn. Due to the advanced design of this spinneret, this machine part can be used under high temperature and high pressure. It consists of a number of holes with specific diameter and shape. The cross sectional design of fiber filament depends on the design of its holes to a great extent. We are proud to introduce ourselves as a growth oriented manufacturer and exporter of premium quality Stainless Steel Hollow Fiber Spinning Spinneret.

Features:

- The offered spinneret has high tensile strength

- Apart from its easy installation technique, this spinneret is preferred for its trouble free operation

- Reasonable price

- Consists of a number of holes

Precision Engineering for Industrial Fiber Production

This spinneret is crafted with a keen focus on accuracy and durability, offering tolerances as tight as 0.01 mm, supporting hole diameters as small as 0.02 mm. CNC machining ensures each unit meets the highest performance standardsideal for hollow and synthetic fiber manufacturing.

Customizable and Easy to Maintain

Users benefit from a fully customizable designholes, overall size, and dimensions can be ordered to suit any industrial requirement. The detachable construction makes cleaning fast and straightforward, minimizing downtime and supporting consistent product quality.

Durable, High-Performance Construction

Manufactured from corrosion-resistant alloy steel and finished with a polished surface, the spinneret is built to withstand demanding environments. With a high hardness of 5560 HRC and excellent tensile strength, it delivers reliability, even under continuous, high-speed operation.

FAQs of Stainless Steel Hollow Fiber Spinning Spinneret:

Q: How does the Stainless Steel Hollow Fiber Spinning Spinneret benefit industrial fiber production?

A: This spinneret enhances fiber production by providing high precision (0.01 mm tolerance), customizable hole diameters, and robust, durable construction. Its excellent corrosion resistance and compatibility with high-speed, high-output machines ensure reliable, efficient performance in industrial settings.Q: What is the process for cleaning the spinneret?

A: The spinneret is designed to be easily detachable, allowing operators to quickly remove and clean it. This minimizes machine downtime and prevents fiber contamination, maintaining optimal performance and product quality.Q: When should I consider customizing the spinnerets hole size or dimensions?

A: Customization is recommended when your production involves unique fiber diameters, output requirements, or specific machine compatibility. You can specify the number, size, and arrangement of holes, as well as overall dimensions, to perfectly fit your process needs.Q: Where can this spinneret be used?

A: This spinneret is suitable for integration into hollow fiber spinning machines used in various industries, including textiles, filtration, and synthetic fiber manufacturing. Its compatibility with manual or semi-automatic textile machines makes it versatile for different production lines.Q: What materials and finishing processes are used for the spinneret?

A: Each spinneret is made from high-grade alloy steel and receives a polished surface for enhanced durability, corrosion resistance, and smooth operation. The part is CNC machined to achieve precise specifications as per order requirements.Q: How do I order an OEM or custom spinneret?

A: OEM and custom spinnerets can be ordered by specifying your required dimensions, hole configuration, and any particular mounting or threading preferences. Contact the supplier or manufacturer directly to discuss your unique production needs and receive tailored solutions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Spinning Components' category

"Our main international markets are Turkey, five countries in central

Asian, Egypt, Tunisia, Algeria,Vietnam, Indonesia, Pakistan and all the

countries in Latin America."

|

JIANGXI HONGYUAN MACHINERY CO., LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |